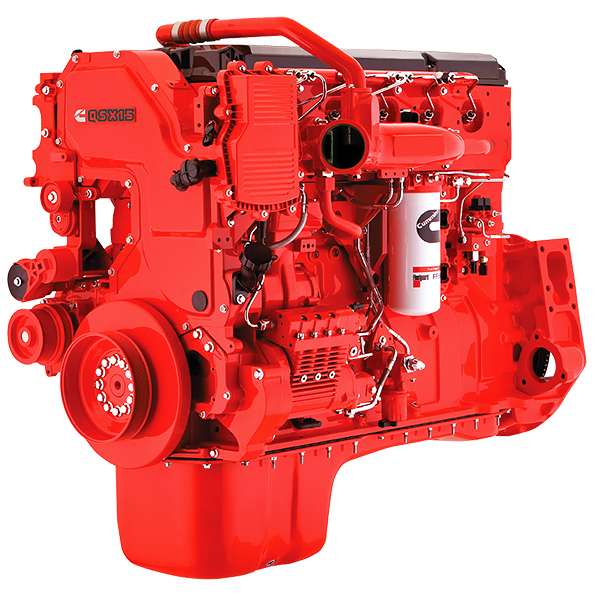

Service technicians have no problem recognising breakdowns and carrying out machine diagnostics, How to Clear Cummins Fault Codes, plus they are familiar with equipment from a variety of manufacturers.

These days it’s nearly impossible to work on or repair a Cummins engine without knowing the fault codes. Once the Cummins fault codes are obtained, the next step is to find out what they mean and also how to clear them.

What Are Cummins Fault Codes?

Fault codes indicate that the engine is experiencing a problem. Every circuit and sensor in a modern diesel engine gives off a certain reading and specific voltage signal.

The Electronic Control Module (ECM) in the engine monitors all the readings constantly as the engine runs. If the values go over or drop under what is expected, then the ECM will log a fault code. There are three fault code statuses:

- Inactive: If it happens at a time outside of diagnostics, then it’s inactive.

- Active: If the error happens during diagnosis, then it’s an active fault.

- Pending: A pending code is one that hasn’t been cleared.

Pending codes can also be intermittent faults or faults that need to be “seen” in at least two warm-up cycles to set them to active. For example, a code can be active after the problem has been repaired. Sometimes several drive cycles are necessary to clear the code out of active status.

There are dozens if not hundreds of fault codes and they are different with each engine, so it’s important to search for information about specific engines when looking for fault codes.

For example, the list of ISX fault codes without EGR prior to 2002 is a different list from the 2007 2010 ISX fault codes with DPF. For the former, the 111 fault code stands for Electronic Control Module. For the latter, 111 has a more specific error: ECM Critical Internal Failure.

The ISX fault codes for the 2007 – 2010 engine are more detailed than the earlier engine. There are many new ones that don’t exist for the previous engine as well. The newer the engine, the more detailed the fault codes in most cases.

How To Clear Cummins Fault Codes

Once any necessary engine repairs have been made, the next thing to know is how to clear fault codes. Software and a diagnostic tool are generally needed for this. Using a code reader tool, connect to the ECM and find the “fault codes” tab.

The displayed codes can generally be clicked on one by one. Another option is to select “erase all faults” and then follow the onscreen instructions. At the end of the procedure, the ignition key should be turned off. Press the appropriate button on the diagnostic tool and turn the key back on.

Depending on the powertrain control module (PCM) software or “flash”, the above procedure might not work. If that’s the case, then an Onboard Diagnostics scanner (OBD-II) can be used to clear the fault codes.

Follow these steps to clear the Cummins fault codes with a scanner:

- Close the doors and insert the key into the ignition

- Cycle the key five times from “off” to “run” without actually cranking the engine

- On the fifth cycle, leave in run

This will clear any pending or currently active codes. It’s important to remember that the “run” position is two clicks of the key. The “accessory” position is only one key click.

Cummins Engine Issues

Even though Cummins engines are generally reliable, they do have some common malfunctions to look out for. Some of them depend on the engine model as well.

Lift pump – This is part of a fairly complex setup for fuel injection. The main issue with this common breakdown is that there are no obvious signs that it’s about to fail. The rest of the injection system compensates for the weakening lift pump, which strains the whole system.

Steel dowel pins vibrations from the engine and temperature fluctuations can cause these pins to shake loose, which can cause quite a bit of damage if it happens. This issue is known by diesel enthusiasts as the “killer dowel pin.” It’s a problem mainly on the 5.9-liter 12 and 24-valve engines made between 1989 and 2002.

The four main places the pin can fall out and get stuck are:

- The timing gear housing and cam gear, but doesn’t damage the housing

- In the oil pan, but doesn’t damage the housing

- Timing gear and cam gear which does damage the housing

- Cam and injection pump gears, which can kill the engine completely

Fortunately, diesel parts shops like ProSource Diesel sell KDP (Killer Dowel Pin) kits to fix and prevent this issue from happening.

- 12-Valve Killer Dowel Pin KDP For 94-98 5.9L Dodge Cummins 24V

- KDP Killer Dowel Pin For 98.5-02 5.9L Dodge Cummins 24V

Misfiring – This is one of the more common issues on any diesel engine, and it usually has something to do with the fuel injectors. Another common reason for misfiring is an electrical problem. Leaky or stuck fuel injectors will cause fuel to leak into the engine oil, which usually makes it easy to identify this problem.

Cracked engine block – This issue is less common than the other three issues, but it can happen. It’s most common on engines made between 1999 and 2002 with a 53 stamp on the block. The issue is due to thin water walls, which can crack and allow coolant to leak into the engine.

If the problem isn’t caught early enough, then a new block may be necessary. Towing and cold-running should be avoided on engines with the 53 stamp.

These are some of the most common Cummins engine issues, but many other problems can crop up as well. The best way to keep any diesel engine in good shape is to follow recommended maintenance schedules to stay on top of preventative repairs and replacements.

Cummins 6.7 Liter Maintenance Considerations

When it comes to following a maintenance schedule, it’s important to remember that some items may need to be addressed sooner depending on whether the diesel truck is used in severe driving conditions.

Any combination or single item of the following list indicates severe driving conditions:

- Excessive idling

- Frequent short trips that keep the engine from reaching full operating temperature

- Driving in dusty conditions

- Off-road driving or conditions that require 4WD

- Frequent heavy towing or hauling

Most service intervals are also the maximum recommended time or mileage before the service should be done. For example, if every 30,000 miles is the recommended interval for a particular service, that’s the maximum amount and the service can and possibly should be done sooner.

The following is a basic list of maintenance considerations for the 6.7-liter Ram truck diesel:

- 15,000 miles or 12 months replace engine and chassis mounted fuel filters

- 30,000 miles or 24 months replace engine air filter (check regularly at oil changes and replace as necessary)

- 60,000 miles or 48 months under normal driving conditions replace transfer case fluid (30,000 miles or 24 months for severe driving conditions)

- 67,500 to 75,000 miles replace crankcase ventilation filter or as indicated by the display (2007.5 2018 engines should be done at 67,500 and 2019+ engines at 75,000 max)

- 100,000 miles replace serpentine drive belt (inspect at oil changes and replace if necessary)

Oil changes on 2007.5 – 2019 Ram truck engines should be done at a maximum of 7,500 miles, six months or 500 hours, whichever comes first. In all cases, the oil change indicator supersedes the intervals.

Cummins 5.9 Liter Maintenance Considerations

The maintenance intervals between the 12-valve and 24-valve version of the second generation Dodge truck engine are very similar. They also use many of the same Cummins parts. How often a Dodge diesel truck is serviced depends on how it’s operated.

As previously mentioned, if it meets any of the severe use considerations, then it should be serviced more often. Every time the truck is serviced, the following items should be done:

- Inspect steering and suspension system and parts for wear

- Inspect exhaust system

- Check all fluid and oil-holding components for leaks

- Check the truck’s parking spot for evidence of leaks

- Inspect brake hoses

- Rotate tires and check for damage

- Check fluid levels

- Check engine air filter

- Drain water from the fuel filter (should be done monthly)

Oil changes for the 12-valve under normal operating conditions should be done every 6,000 miles or six months. For severe operating conditions, it should be done every 3,000 miles or three months.

The 24-valve engine can go up to 7,500 miles or six months before an oil change in normal operating conditions. In severe conditions, it should be done every 3,750 miles or three months.

Fuel filter intervals for the 24-valve are the same as the 6.7-liter, but 12-valve engines should have it replaced every 12,000 miles or 12 months, whichever comes first. These intervals remain unchanged even in severe operating conditions.

When it comes to repairing your heavy-duty Ford truck, Dodge truck or Chevy truck, ProSource Diesel has all the reliable and hard-to-find diesel truck parts and kits you need to keep your rig in good shape. We carry a wide range of parts for Powerstroke and Duramax parts as well.

The diagnosis tool How to Clear Cummins Fault Codes for trucks provides different possibilities such as information on the use and location of the connectors, detection and description of errors, activation of the fan, compression test and other components, system data information and more.

JCB Fault Codes List

JCB Fault Codes List

MAN TGA Fault codes list

MAN TGA Fault codes list

CHALLENGER Tractor Fault Codes DTC

CHALLENGER Tractor Fault Codes DTC