Service technicians have no problem recognising breakdowns and carrying out machine diagnostics, Error Codes Volvo Truck, plus they are familiar with equipment from a variety of manufacturers.

Note:

Note:

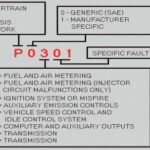

FMI 0 Data reliable, but above normal;

FMI 1 Data reliable, but below normal;

FMI 2 Incorrect data;

FMI 3 Short circuit to a high voltage circuit or high voltage;

FMI 4 Short circuit to low voltage or low voltage;

FMI 5 Open circuit or low current;

FMI 6 Abnormal current or short circuit to ground;

FMI 7 Malfunctioning mechanical system;

FMI 8 Invalid pulse frequency;

FMI 9 Invalid refresh rate;

FMI 10 large fluctuations;

FMI 11 Unknown malfunction;

FMI 12 Faulty component;

FMI 13 Invalid calibration value;

FMI 14 Special Instructions;

FMI 15 Reserve for future use.

| The code | Parameter | Fmi | Malfunction | ||||||||||

| PID21 | ICE fan speed | 3

8 |

The voltage at the contact of the engine block EA 6 is higher than 65% of the battery voltage, a short to positive, a break in the power or ground wire, a sensor malfunction on the fan. The fan rotates at maximum speed, which causes high fuel consumption. The ICE unit detected excess pulses in the fan speed signal, the wiring is damaged or the insulation of the wires is poor, the sensor on the fan is faulty, the fan is faulty. The fan rotates at maximum speed, which causes high fuel consumption. |

||||||||||

| PID45 | Pre -heating of air | 3

4 5 |

The wire between the engine control unit from contact EB 31 and relay K 48 closes to a constant plus, relay K48 is faulty. Starting ICE in cold weather is difficult. The code is only active if the ignition key is in the preheating position (between the ignition switch position and the engine start position) The wire between the engine control unit from terminal EB31 and relay K48 closes to ground, the preheating relay K48 is faulty. The air heater is constantly activated, as a result of overheating, the heating spiral can be destroyed and parts of the spiral can get into the intake manifold of the internal combustion engine and into the valve mechanism.

Open circuit, fuse for heating relay fuse blown, wire break between engine control unit and relay, open relay power wire. Heating does not turn on ; starting in cold weather is difficult . |

||||||||||

| PID81 | Particle Filter Pressure Difference |

|

|

||||||||||

| PID84 | Vehicle speed | 9

eleven |

Faulty speed sensor, error of data channel data SAE J 1708, error in the vehicle control unit ( VECU ). If FMI 11 is present , the engine speed does not exceed 1700 rpm. Check the integrity of the data channel wiring. There is no or incorrect speed signal transmitted via the data channel SAE J 1939, the speed sensor is faulty, the data channel SAE J 1939 is faulty, the vehicle control unit ( VECU ) is faulty . The speed signal is transmitted via the data channel SAE J 1708. If FMI 9 is present , the engine speed does not exceed 1700 rpm. Check the integrity of the data channel wiring . | ||||||||||

| PID85 | Speed system status | 9 | Error data channel data SAE J 1708, an error in the vehicle control unit ( VECU ). Check the integrity of the data channel wiring . | ||||||||||

| PID91 | The position of the pedal accelerator | 9

eleven |

The signal of the position of the accelerator pedal is incorrect or missing, the sensor on the accelerator pedal is faulty, the data channel is SAE J 1587 / J 1708, the error is in the vehicle control unit ( VECU ). If FMI 11 is present , the engine block enters idle mode. Check data channel J 1587 / J 1708 between the engine block and the MA connector (junction box under the radiator grille on the left) and from the MA connector to the CLF connector (junction box in the center of the dashboard). If the wiring is normal, replace the accelerator pedal. The pedal position signal is not transmitted through the data channel SAE J 1939, the sensor on the accelerator pedal is faulty, the data channel SAE J 1939 is faulty , the error is in the vehicle control unit. If FMI 9 is present , the engine block enters idle mode. Check the integrity of the data channel , replace the accelerator pedal . | ||||||||||

| PID94 | Fuel pressure | 1

3 4 7 |

For D 6 B , D 7 C , D 10 B , D 12 C engines : Fuel pressure is below normal. The fuel filter is clogged, fuel leakage, air leaks, the bypass valve opens at low pressure, the mechanical pump does not pump well or the sensor is faulty. Perform a fuel pressure check with a pressure gauge. For D 16 B engine : Fuel pressure above normal (over 700 kPa). The fuel filter is clogged, the bypass valve does not open. The voltage at the EA27 contact of the engine block is higher than 4.95 V. The wire is shorted to power or to the signal wire. The sensor may be defective. The voltage at the EA27 contact of the engine block is below 0.08 V. A break in the power wires, signal, or ground of the fuel pressure sensor. Probably defective sensor. Fuel pressure below normal. The fuel filter is clogged, fuel leakage, air leakage, the bypass valve opens at low pressure, the mechanical pump does not pump well, the sensor is faulty . Perform a fuel pressure check with a pressure gauge . |

| PID97 | Water Separator Indicator | 3

4 14 |

The voltage at the contact of the engine block EV6 exceeds 91 % of the battery voltage. Short to power or signal wire, open signal wire. The indicator may be malfunctioning. The voltage at the contact of the engine block EV6 below 5% of the battery voltage. Short to negative or to signal wire. The indicator may be malfunctioning. The code informs that the electric fuel pump is switched on. Not a malfunction code. |

| PID98 | ICE oil level | 1 45 |

Low engine oil level, level sensor defective. The voltage at the contacts of the engine block EV15-EV22 is lower than 0.5 V. A short to negative or to a signal wire. The level sensor may be defective. The voltage at the contacts of the engine block EV15-EV22 is higher than 4.95 V. Breakage of the signal wire or ground wire. The closure on the conductive power or weight . Probably defective sensor . |

| PID100 | ICE oil pressure | 1

3 4 |

Low oil level. Liquid, thick, dirty oil. Bypass valves, oil pump, pressure sensor may be faulty. The voltage at the contact of the engine block EA14 is higher than 4.95 V. A short to voltage or signal. Perhaps defective defective sensor. The voltage at the contact of the engine block EA14 is below 0.08 V. An open of the power wire or sensor signal. Short to negative or to signal wire. Probably defective sensor. |

| PID102 | Charge air pressure | 3

4 |

The voltage at the contact of the engine block EA3 is higher than 4.95 V. A short to voltage or signal. Probably defective sensor. The voltage at the contact of the engine block EA3 is below 0.08 V. Breakage of the power wire or sensor signal. Short to negative or to signal wire or defective sensor. |

| PID105 | The temperature of the injected air | 3

4 |

The voltage at the contact of the engine block EA2 is higher than 4.95 V. A short to voltage or signal or the sensor is faulty. The voltage at the contact of the engine block EA2 is lower than 0.08 V. An open of the power wire or sensor signal. Short to negative or to signal wire or defective sensor. |

| PID107 | Pressure drop in the air filter | 0

3 4 5 |

Large differential pressure, clogged air filter or defective differential pressure sensor on the air filter. The voltage at the EB3 contact of the engine block from the sensor on the air filter exceeds 91% of the battery voltage. Short to power, signal or ground. Probably defective sensor. The voltage at the EB3 contact of the engine block from the sensor on the air filter is less than 9% of the battery voltage. Short to ground or signal or sensor defective. The voltage at the EB3 contact of the engine block from the sensor on the air filter is from 63 to 91% of the battery voltage. Open wire signal , ground or defective sensor . |

| PID108 | Atmospheric pressure (the sensor is located inside the engine block) | 3 4 |

The sensor signal is higher than 4.95 V. The engine block is faulty. Sensor signal below 0.08V. Defective engine block. |

||||||||||||

| PID110 | The temperature of the cooling fluid ICE | 0

3 4 |

The temperature of the coolant exceeds 102 degrees. There is no liquid, thermostat or water pump malfunction, the radiator of the cooling system is clogged inside or outside, the intercooler ( intercooler ) is clogged from the outside or the liquid temperature sensor is faulty. The voltage at pin EA25 from the temperature sensor is higher than 4.95 V. The signal wire is shorted to the power wire. Broken ground wire or signal. Probably defective sensor. The voltage at pin EA25 from the temperature sensor is below 0.08 V. The signal wire is shorted to ground, the sensor is faulty. |

||||||||||||

| PID111 | The level of the cooling liquid | 1

3 4 |

The voltage at the EB 7 contact of the engine block from the level sensor is less than 45% of the battery voltage. Low coolant or short to ground on signal wire. Probably defective sensor. The voltage on the EV7 of the engine block from the level sensor exceeds 95% of the battery voltage. Short to power wire, 24V circuit, or signal wire or level sensor defective. There is no voltage at the EB7 contact of the engine block from the level sensor. Short to ground or signal wire. The level sensor may be defective. |

||||||||||||

| PID131 | Reverse pressure exhaust |

|

|

| PID153 | The pressure in the crankcase of the internal combustion engine | 0

3 4 |

Crankcase pressure above 8 kPa. Crankcase ventilation clogged. Piston ring wear is possible or crankcase pressure sensor is defective. The engine stalls at a speed of less than 2 km / h. The voltage at the EB24 contact of the engine block from the sensor exceeds 4.95 V. A short to voltage, signal, or the sensor is faulty. The voltage at the EB24 contact of the engine block from the sensor is below 0.08 V. An open of the power or signal wires. Short to ground , signal wire or defective sensor . |

| PID158 | Battery voltage | 3

4 |

The voltage at the contacts EB11, EB12 of the engine block from the batteries is higher than 36 V. The generator is faulty or the starting device is connected. The voltage at the contacts EB11, EB12 of the engine block from the batteries is lower than 12 V. The generator or the low battery is faulty. Partial damage to the wires or battery terminals is possible . |

| PID163 | Transmission Range Reached | 1 2 |

|

||

| PID171 | Outside air temperature (air filter sensor) | 9 | Incorrect or missing sensor signal. Sensor defective, data channel error SAE J 1587 / J 1708. There may be a malfunction in the engine block . |

| PID173 | The temperature of the exhaust gases | 0 45 |

Too high temperature. The influence of external conditions such as driving style and climate. The voltage at the EB18 contact of the engine control unit from the temperature sensor is below 0.04 V. A short to ground, a signal wire, or the sensor is faulty. The voltage at pin EB18 is higher than 4.95 V. A short to voltage from the battery. Broken signal or power wire . Probably defective sensor . |

| PID175 | ICE oil temperature | 0 34 |

The engine oil temperature is above 125 degrees. Inadequate cooling or defective sensor. The voltage at the EA1 contact of the engine block from the temperature sensor is higher than 4.95 V. A short to voltage or signal. Broken power wire or sensor malfunction. The voltage at the EA1 contact of the engine block from the temperature sensor is below 0.08 V. A short to ground or to a signal wire. Probably defective sensor . |

| PID190 | High speed engine | 0 | The engine speed is above 2500 rpm. Incorrect gear selection

during engine braking. Oil entering the combustion chamber of the engine. A faulty turbocharger drives the oil into the engine inlet. After replacing the turbocharger that expelled the oil, the remaining oil is not drained from the intercooler ( intercooler ). Possibly defective closed ventilation crankcase ( with the presence in the complete set ). |

| PID224 | Car security code ( immobilizer ) | 2

12 |

Invalid response from immobilizer block . The immobilizer block code does not match the engine block code. Incorrectly programmed engine block or immobilizer block . There is no response from the immobilizer block . A break in the wiring between the engine block and the immobilizer block or the immobilizer block is faulty . |

| PID228 | Speed Sensor Calibration Data | eleven | Calibration coefficient “K” is not transmitted

via data channel SAE J 1708. Data channel error or error in the VECU vehicle control unit . |

||||||||

| PID245 | The total mileage of the car | 9 | Post run of the vehicle is not transmitted on

the data channel SAE J 1708 / J 1587. Fault channel data or failure of the instrument panel . |

||||||||

| PID251 | Post by SAE J1708 | 9 | Lost message on SAE J 1708 data channel. Data

channel interruption between the internal combustion engine and the vehicle control unit ( VECU ). |

||||||||

| PID252 | Post by SAE J1708 | 9 | Lost message on SAE J 1708 data channel. Data

channel interruption between the internal combustion engine and the vehicle control unit ( VECU ). |

||||||||

| PID411 | ICE exhaust pressure difference | 3

5 |

The voltage at the EA21 contact of the engine

block is higher than 5.5 V. The back pressure sensor or wiring is faulty. engine block from the back pressure sensor is higher than 4.95 V. A short to voltage, signal. Open wire signal , power or ground . Probably defective sensor . |

||||||||

| PID412 | EGR temperature |

|

|

| The code | Parameter | Fmi | Malfunction |

| SID1

SID2 SID3 SID4 SID5 SID6 |

Wheel speed sensor, axis 1, left Wheel speed sensor, axis 1, right Wheel speed sensor, axis 2, left Wheel speed sensor, axis 2, right Wheel speed sensor, axis 3, left Wheel speed sensor, axis 3, right |

0 1 23 4 56 7 8 9 10 11 14 |

Incorrect sensor connection. Check wiring and sensor connector. The gap between the sensor and the gear is incorrect. Check the clearance (not more than 0.7 mm.) Large clearance between the sensor and the gear, the gear is crooked or dirty. Check the gear, the clearance of the sensor (not more than 0.7 mm.), The play of the wheel bearing. Shorting one of the wires to plus. Check wiring and sensor connector. Shorting one of the wires to minus. Check wiring and sensor connector. Open circuit, short to positive or negative, defective sensor, defective modulator. Check wiring, check sensor resistance. If the wires and sensor are normal, replace the modulator. Short circuit between wires. Check wiring and sensor resistance. Large gap between the sensor and the gear, the sensor is defective. Check sensor wires, clearance (not more than 0.7 mm.), Gear integrity. If the wires and gear are intact, replace the sensor. To reset the code, RESET 2 . Shorting the sensor signal to another signal. Check wires, sensor resistance . If the wires and sensor are normal, replace the modulator. Incorrect setting of the wheel circumference, a large gap between the sensor and the gear wheel, the wheel brakes without pressing the brake pedal, the wheel is lowered or punctured, different wheel circumferences on the right and left sides. Check brake mechanisms, gears, difference in wheel circumference. To reset the code, RESET 2. A large gap between the sensor and the gear wheel, the contacts and wires are damaged, the gear wheel is damaged, the sensor is faulty, the modulator is faulty. Check wheel bearing play, sensor wiring, clearance (not more than 0.7 mm.), Gear. If everything is normal, replace the modulator. To reset the code, perform RESET 2. Vibration during braking. Check brake mechanisms. Control unit malfunction or electromagnetic interference. Contact the service station. Incorrect data set in the control unit, incorrect wheel circumference. To reset the code, perform RESET 2. Electronic components in the modulator are not working. Replace the modulator. Note: Sensor resistance for ABS 1150 + 100 / -50 ohm, for EBS 1600 + 100 / -100 ohm. |

| SID7

SID8 SID9 SID10 |

ABS valve , axis 1, left ABS valve , axis 1, right ABS valve , axis 2, left ABS valve , axis 2, right |

1

3 5 |

Open two control wires, open negative cable. Check the wires between the ABS unit and the valve. Shorting the control wires to plus, shorting to the wire of another valve. Check wiring of all ABS valves . Open of one of the control wires. Check control wires. Shorting the control wires to minus. Check control wires. |

| SID7

SID8 SID9 SID10 SID11 SID12 |

Modulator, axis 1, left Modulator, axis 1, right Modulator, axis 2, left Modulator, axis 2, right Modulator, axis 3, left Modulator, axis 3, right |

0

1 2 3 4 5 6 7 8 9 10 eleven 12 thirteen 14 |

The modulator silencer is clogged, the modulator internal malfunction, leak through the foot brake valve, air leak in the brake cylinder. Check the modulator muffler, pressure on the modulator without depressing the brake pedal. To reset the code, RESET 1 . The modulator muffler is clogged, the air lines are clogged or damaged, there is a mechanical failure in the modulator or in the foot brake valve. Check modulator muffler, check air lines. To reset the code, perform RESET 1. Electromagnetic interference, internal fault in the modulator, EBS control unit is faulty . Check wires, contacts, connectors. Short circuit of the modulator power wire to a constant plus from the battery, internal malfunction in the EBS unit . Check for short circuits in the modulator circuit. Short circuit of the power wire to minus, internal malfunction in the modulator, malfunction in the EBS unit . Check for short circuits in the modulator circuit. The voltage on the modulator is absent or too low. Check the power of the modulator, the absence of a short in the supply wire to minus. High voltage on the modulator, damaged wires, defective EBS unit . Check the modulator wiring for a short. If the wires are normal, replace the EBS unit . The modulator muffler is clogged, the modulator is defective. Check and clean the modulator muffler; if the muffler is normal, replace the modulator. Air tubes clogged or damaged, modulator or ABS valve defective . Check the tubes from the modulator to the ABS valve , check the air pressure on the modulator. If all of the above is normal, replace the modulator. Try RESET 1. Short circuit, wire break, software failure, modulator faulty, EBS block faulty . Check the wiring between the modulator and the EBS unit , reprogram the EBS unit , replace the modulator, replace the EBS unit . The modulator is faulty, the power of the modulator is turned off until the completion of internal operations (for example, turning off the batteries with the ignition on). Delete error codes, if the fault reappears, replace the modulator. Faulty modulator, faulty EBS unit . If one modulator fails, replace the modulator. If several modulators fail, replace the EBS unit . Faulty modulator, modulator wiring, EBS unit . Delete error codes, check the wiring of the modulator, if the fault reappears, replace the modulator. The modulator is replaced by a modulator with a different catalog number. Check the correspondence of the modulator number, reprogram the EBS block . Damaged, leaking or clogged modulator tubes or brake cylinder tubes, insufficient air on the modulator, defective modulator, clogged muffler. Check air lines, modulator silencer, air pressure at the inlet to the modulator. Try to perform the RESET 1. |

| SID13 | Disable additional brake | 3 5 6 |

Shorting the wire between the ABS and VECU units is a plus. Check wiring between these units. Open circuit between the ABS and VECU . Check wiring between these units. Circuiting the wires between blocks ABS and VECU on minus . |

| SID14 | Valve Power ABS | 3 45 6 7 |

Short wires between the block ABS , and the solenoid valve ABS to plus. Blown fuse No. 2 (basic version) or No. 3 (full version) of the solenoid valve power supply, open circuit of the ABS unit power wire . Break in the mass wire of the ABS unit . Short to ground wire of the solenoid valves. Defective ABS unit . |

| SID22 | Wheel Speed Sensor Signal | 14 | The wheel speed sensor is not connected correctly. Check wiring and connectors of all speed sensors. Check if the right and left speed sensors are mixed up. To reset the code after troubleshooting. |

| SID23 | ABS lamp on the dashboard | 5 | Shorting the wire to minus, a wire break between the ABS unit and the lamp, the lamp holder is damaged, the lamp burned out. |

| SID24 | Lamp TCS switch TCS | 3

4 |

Shorting the wire from the lamp to the EBS unit is a plus. Check lamp control wire for short circuits. Shorting the wire from the lamp to the EBS unit by minus, the LED in the switch is faulty. Check lamp control wire, check TCS switch wires for an open. |

| SID57 SID60 |

Pressure difference in modulators | 2 | Clogged, pinched, leaking air tubes, defective modulator. Check the air supply to the modulators. Note: SID 57 refers to front modulators, SID 60 refers to dual leading axis modulator. |

| SID66 | Trailer brake control modulator (mounted on tractor) | 0

2 3 6 |

Damaged wiring, loose contact in the connector, internal malfunction in the trailer modulator, faulty modulator, faulty EBS unit . Check the wires between the EBS unit and the trailer brake control modulator. The modulator configuration is not correct, the wires are damaged, the EBS unit is malfunctioning . Check wiring and connectors. Short circuit of the modulator wires to plus, damaged wires, internal malfunction in the EBS unit . The wires are damaged, the modulator is faulty, the control unit is faulty. Check power wires and data channel wires between the modulator and the EBS unit . Damaged wiring , defective modulator , defective EBS unit . |

| SID67 | Trailer brake control modulator pressure sensor | 0

1 7 8 12 14 |

There is no parking brake signal, the trailer modulator is incorrectly connected, wires or contacts in the connectors are damaged, the foot brake valve is damaged or incorrectly connected, the trailer modulator is faulty. Check the parking brake signal, wires and contacts in the connectors, the correct connection of the trailer modulator and foot brake valve. If everything is normal, replace the trailer modulator. Try to RESET 1. Internal malfunction of the trailer modulator, the supply pressure signal is incorrect, the air supply line to the trailer modulator is damaged. Check air tubes. If there are no faults in the lines and in the pressure switch, replace the modulator. Try to do 1. Air lines are clogged or leaky, the hand brake does not work, the foot brake valve is not connected correctly, the trailer modulator is faulty. Check the air lines between the trailer modulator and the foot brake valve. Check the connection of the foot brake valve. Check the air lines between the trailer modulator and the hand brake valve. If there are no malfunctions associated with the foot brake valve , replace the trailer brake control modulator. Try RESET 1. Faulty trailer brake control modulator. Replace trailer modulator. Try RESET 1. The parking brake is not correct or not. Check the parking brake signal. If the parking brake signal is normal, replace the trailer modulator. Try to RESET 1. The pressure sensor in the trailer modulator is faulty, high air pressure on the modulator. Check the air supply pressure to the modulator. Try to RESET 1. If the pressure is normal and the restart does not produce results, replace the modulator. |

| SID68 | Trailer Modulator Pressure Sensor Power | 1

3 4 7 |

Wire breakage between the modulator and the EBS block , invalid data set in the EBS block . Check the wires, reprogram the EBS unit . Open wire, defective EBS unit . Check the wires and contacts in the connectors, if normal, replace the EBS unit . Broken wires, defective EBS unit , defective trailer modulator. Check the wires between the EBS unit and the trailer modulator, also check the contacts in the connectors. Broken wires, faulty pressure sensor in the trailer modulator, faulty EBS unit . Check wiring between trailer modulator and EBS unit . Check the inlet pressure to the trailer modulator (must not exceed 8.5 Bar . If the wiring and pressure are normal , replace the trailer modulator . |

| SID69 | Sensor load on axle | 2 | Broken wires between the sensor by the rear axle modulator, shorted wires from the sensor to the modulator to ground or plus, the sensor or modulator is faulty. Check the wires and contacts in the connectors . |

| SID70

SID71 SID72 SID73 SID74 SID75 |

Brake pad wear sensor, axle 1, left Brake pad wear sensor, axle 1, right Brake pad wear sensor, axle 2, left Brake pad wear sensor, axle 2, right Brake pad wear sensor, axle 3, left Brake pad wear sensor, axis 3, right |

0

1 3 10 12 |

The wear sensor is faulty, the modulator is faulty, the wiring or the contacts in the connectors are damaged. Check the wires and contacts, replace the wear sensor, in extreme cases, replace the modulator. The wear sensor is faulty, the modulator is faulty, the wiring or the contacts in the connectors are damaged. Check the wires and contacts, replace the wear sensor, in extreme cases, replace the modulator. Faulty modulator, short circuit in wiring to plus. Check the wiring for a short between the modulator power and the wear sensor. The signals of the right and left wear sensors differ by more than 20%. The caliper is defective, the pads are not worn out evenly. Check the condition of the pads, check the brake caliper mechanisms. Short circuit of the power supply wires of the wear sensor to minus, the modulator is faulty. Check wiring between wear sensor and modulator. |

| SID76 | Foot brake valve | 2

3 4 12 14 |

Damaged wires or contacts in the connectors between the EBS unit and the foot brake valve, the valve is defective, the EBS unit is faulty . Check wiring and connectors, replace foot brake valve, in extreme cases, replace EBS unit . The foot brake valve is faulty, the wires or contacts in the connectors are damaged, the EBS unit is faulty . Check the wiring between the EBS unit and the foot brake valve for shorts and breaks, replace the foot brake valve, in extreme cases, replace the EBS unit . The foot brake valve is faulty, the wires or contacts in the connectors are damaged, the EBS unit is faulty . Check the wiring between the EBS unit and the foot brake valve for shorts and breaks, replace the foot brake valve, in extreme cases, replace the EBS unit . Incorrectly connected foot brake valve, mechanical valve malfunction, EBS unit defective . Check the brake pedal free play (4-8 mm.), Check the connection of the foot brake valve. The brake pedal does not return to the depressed position; the foot brake valve is defective. Check that the valve is installed correctly. Try RESTART 1. |

| SID79 | Wheel tire size | thirteen | Invalid tire size in EBS unit, EBS unit fault . Replace the EBS unit . |

| SID221 | Internal power sensor | 3

4 |

Checking the power supply of the foot brake valve gave an incorrect result, the power of the valve is higher than 5.2V, the wires or contacts in the connectors between the EBS unit and the foot brake valve are damaged, the EBS unit is faulty . Check wiring and contacts in the connectors, in extreme cases, replace the EBS unit . Checking the power supply of the foot brake valve gave an incorrect result, the power of the valve is lower than 4.8V, the wires or contacts in the connectors between the EBS unit and the foot brake valve are damaged, the foot brake valve is faulty, the EBS unit is faulty . Check wiring and contacts in the connectors, check the operation of the foot brake valve, in extreme cases, replace the EBS unit . |

| SID231 | SAE J1939 Data Channel | 5

2 6 9 12 |

Broken wire or wires of the data channel, short circuit to plus or minus, short circuit of the bus wires to each other. Check the integrity of the data channel wires. Electromagnetic interference, data channel failure between the EBS unit and other control units. Check data channel integrity. Broken wire or wires of the data channel, short circuit to plus or minus, short circuit of the bus wires to each other. Check the integrity of the data channel wires. Failure of the data channel SAE J 1939, the engine control unit is faulty, the engine control unit software was replaced. Check the integrity of the data channel wires. Malfunction in the block EBS . Check the integrity of the data channel, in extreme cases, replace the EBS block . |

| SID240 | Program memory | 2

12 |

An incorrect program was installed in the EBS block ; a failure occurred during the installation of the program. Program the EBS block . If the error persists, replace the EBS unit . The program in the EBS block is working with errors, not the correct software. Program the EBS block . If the error persists, replace the EBS unit . |

| SID251 | ABS unit power | 3 | The power supply voltage of the unit is higher than 32 V for more than 5 seconds, electric welding was performed, an external power source was connected, the generator was faulty. Check power supply to the ABS unit . |

| SID251 | EBS unit power | 3

5 |

Open or short to minus the power supply wires of the EBS unit, the EBS unit is faulty . Check power cord. In extreme cases, replace the EBS unit . Damaged wiring or contacts in the connectors, defective EBS unit . Check the voltage of the EBS unit , the wiring and the contacts, the voltage of the batteries. If everything is OK , replace the EBS unit . |

| SID253 | EEPROM , calibration memory (for EBS ) | 2

10 12 thirteen |

An error in the internal memory of the EBS block , incorrect parameter values, the EBS block is faulty . Program the EBS block . If the error persists, replace the EBS unit . An error in the internal memory of the EBS block , incorrect parameter values, the EBS block is faulty . Program the EBS block . If the error persists, replace the EBS unit . Error in the internal memory of the EBS unit , the battery power was turned off when the ignition is switched on, the EBS unit is faulty . Program the EBS block . If the error persists, replace the EBS unit . Incorrect configuration of ESP to block the EBS , defective block the EBS , the wrong software. Program the EBS block . If the error persists, replace the EBS unit . |

| SID253 | EEPROM , calibration memory (for ABS ) | 2 12 |

Invalid wheel setting. Check calibration memory. Checksum is not correct, failure while connecting diagnostic equipment. Check calibration memory . |

| SID254 | Block EBS | 1

2 5 6 12 13 14 |

During the check, a fault was found in the EBS unit , and a faulty EBS unit was found . Press the brake pedal twice. If the error appears again, replace the EBS unit . Internal malfunction of the EBS unit . Replace the EBS unit . When the ignition is off, the EBS unit is active, the power of the modulators is constantly on. Check the wiring and contacts in the connectors for a short to constant plus from the batteries, the EBS unit is faulty . Check wiring and contacts in the connectors between the EBS unit and the foot brake valve. Check the wiring and contacts in the connectors between the EBS unit and the modulators. Reprogram the EBS block . If the error appears again, replace the EBS unit . The wires between the EBS unit and the modulator are damaged, the EBS unit is faulty . Check the wiring and contacts in the connectors between the modulator and the EBS unit . Press the brake pedal; if the error reappears, replace the EBS unit . Internal malfunction of the EBS unit . Replace the EBS unit . High temperature block EBS . Check if the EBS unit is heating up from an external heat source. If the temperature is normal, replace the EBS unit . Faulty EBS block . Perform RESET 5 , reprogram the EBS block . If the error persists, replace the EBS unit . The internal parameters in the EBS unit are not correct, the vehicle configuration does not correspond to the technical specifications, incorrect software, a malfunction of the EBS unit . Reprogram the EBS block . If the error appears again, replace the EBS unit . Faulty EBS block . Run restart №5 , reprogram the unit the EBS . If the error persists, replace the EBS unit . |

| SID254 | ABS block | 2 589 12 |

Internal malfunction of the ABS unit . Perform an ABS block check . Replace ABS unit . No load was detected at the terminals of the ABS valves ; no ABS valves were connected . Check the wires and the contacts in the connectors of the unit ABS to valves ABS . Perform an ABS block check . The rotational speed of one axis is higher than the other. The car was towed with the raising of one of the axles. Perform an ABS block check . A signal from the ABS sensor indicates that the wheel is locked and does not unlock when the pressure is adjusted by the ABS valve . Perform an ABS block check . Internal malfunction of the ABS unit . Perform an ABS block check . Replace ABS unit . |

| The code | Parameter | Fmi | Malfunction |

| PID96 | Fuel level sensor | 5

6 |

The resistance at contacts B3 and A12 of the dashboard unit from the sensor in the tank is more than 1 kOhm. Broken signal or negative wire, oxidation or damage to the contacts in the connectors. The sensor may be defective. The resistance at contacts B3 and A12 of the dashboard block from the sensor in the tank is more than 20 Ohms. Shorting the signal wire to ground or the sensor is faulty. |

| PID114 | Ammeter | 3

4 |

The signal wire is shorted to a higher voltage or the sensor is faulty. The sensor is located in the battery box. Open or short to ground signal wire. Probably defective sensor. |

| PID117 | Front air pressure sensor | 3

4 |

Broken negative wire or shorted signal wire to a wire with a higher voltage. Probably defective sensor B152. The sensor is located to the left of the radiator grille under the cowl on the driver’s side. Broken power wire, sensor signal, shorted signal wire to ground, oxidized or damaged contacts in the connectors. |

| PID118 | Rear air pressure sensor | 3

4 |

Broken negative wire or shorted signal wire to a wire with a higher voltage. Probably defective sensor B153. The sensor is located to the left of the radiator grille under the cowl on the driver’s side. Broken power wire, sensor signal, shorted signal wire to ground, oxidized or damaged contacts in the connectors. |

| PID158 | Battery voltage | 3

4 |

Battery voltage is higher than 31 V. The device for starting is connected, the generator or the battery is faulty. Voltage below 8 V. or voltage when the engine is running below 24 V. more than 250 seconds. Defective generator or battery . |

| PID171 | Sensor temperature outdoor air | 5

6 |

The resistance at contacts B9 and A12 of the dashboard block from the sensor is more than 25 kOhm. Open signal or negative wire. Oxidation or damage of contacts in connectors. Defective sensor or outside temperature below 50 degrees. The sensor is located under the footrest on the passenger side. The resistance at terminals B9 and A12 of the dashboard block from the sensor is less than 25 kOhm. Shorting the signal wire to ground, the sensor is faulty or the outside temperature is above 90 degrees. |

| PID177 | Gearbox oil temperature sensor | 5

6 |

The resistance at contacts B12 and A12 of the dashboard block from the sensor is more than 5 kOhm. Open signal or negative wire. Oxidation or damage of contacts in connectors. Sensor defective. The resistance at terminals B12 and A12 of the dashboard block from the sensor is less than 10 kOhm. Short circuit of signal wire to ground or defective sensor. The gearbox oil temperature is very high. |

| PID252 | Current date | 9 | Date or time data sent by the car control unit or tachograph unit via the data channel is incorrect or missing. A malfunction in the data channel or damaged contacts in the connectors. |

Fault codes for Volvo truck engine control units until 1998. FH12 with D12A engine TD122, TD123, TD103, TD163 engines.

| The code | Parameter | Fmi | Malfunction |

| PID170 | Cabin air temperature sensor. | 3

4 |

The climate control unit registers the voltage in the temperature sensor circuit above 4.86 V. The sensor is not connected to the control unit. It is possible that the signal or ground wire is shorted to a higher voltage. The climate control unit registers the voltage in the temperature sensor circuit below 0.7 V. The signal wire is shorted to ground or the sensor is faulty. |

| PID171 | Sensor temperature outdoor air . | 3

4 |

The climate control unit registers the voltage in the temperature sensor circuit above 4.9 V. Shorting the signal or ground wire to a higher voltage. Probably defective sensor. The climate control unit registers the voltage in the temperature sensor circuit below 0.55 V. The signal wire is shorted to ground or the sensor is faulty. |

JCB Fault Codes List

JCB Fault Codes List

Fault Codes and diagnostic code Information for Caterpillar Control

Fault Codes and diagnostic code Information for Caterpillar Control

MAN TGA Fault codes list

MAN TGA Fault codes list